“CLAS CO.” with more than 42 years of experiences, and use of expert staff including most equipped with sophisticated Equipment.

CLAS CO. is capable of presenting engineering and alignment services in order to implement all the

CLAS CO. is capable of presenting engineering and alignment services in order to implement all the tasks involved (Shaft Alignment, GEO & Line Bore Alignment Applications) to various industries such as Power Plants, Oil & Gas, and Petrochemical Industries.

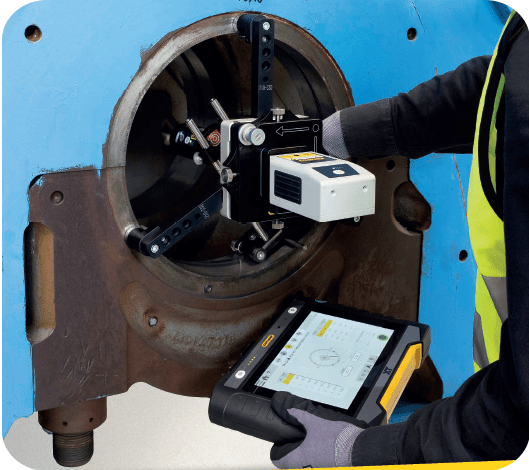

We have our own EASY LASER SYSTEM FOR LINE BORE ALIGNMENT made in Sweden.

VERSATILE, EASY AND PRECISE

BORE ALIGNMENT FOR A WIDE RANGE OF APPLICATIONS

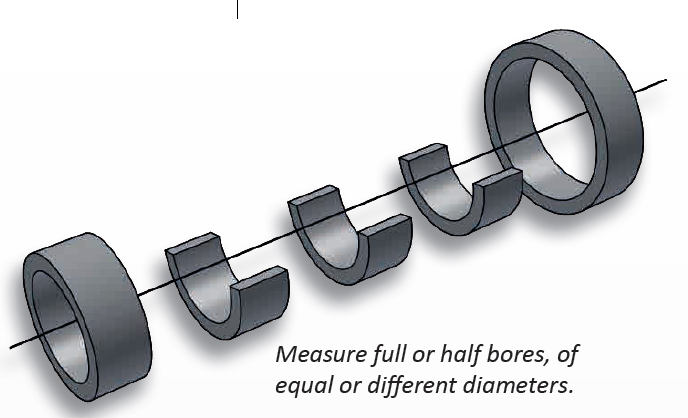

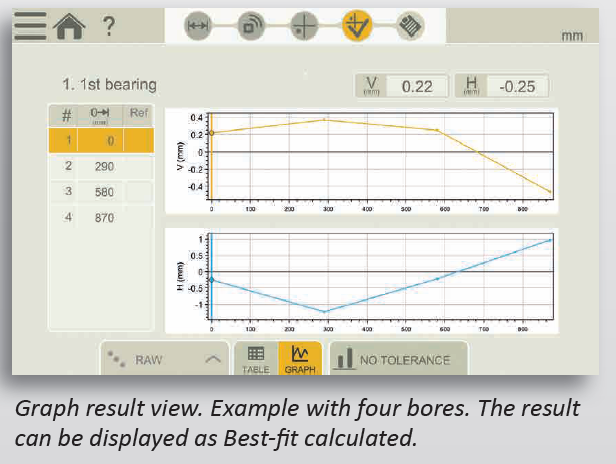

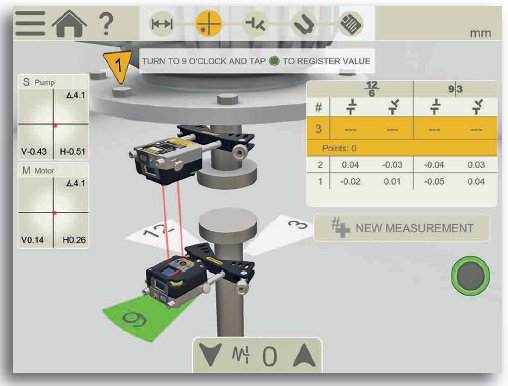

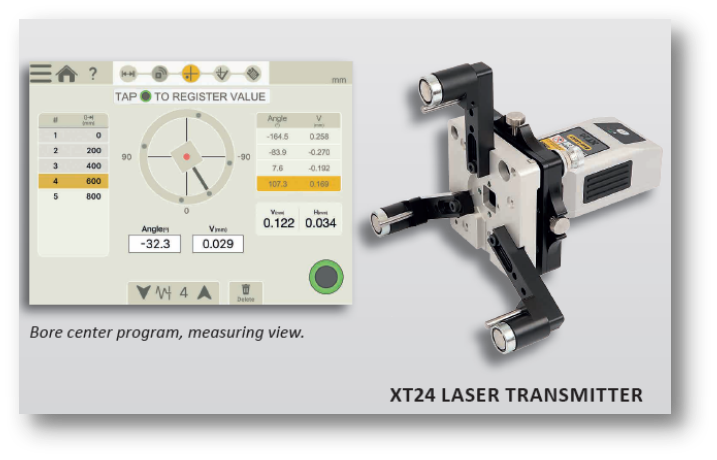

The Easy-Laser® XT Bore alignment solutions are primarily designed for applications like engines, compressors and gear boxes, but can be used in many more applications. All parts are designed for maximum accuracy and stability, and meas ure with a resolution of 0.001 mm [0.05 mils]. Measurement distance up to 40 m [130 feet]. They are suitable for use both in manufacturing and in field services activities.

FOR OTHER STRAIGHTNESS MEASUREMENTS

We can also measure the straightness of shafts, linear guides, foundations, etc. without any additional accessories.

Our team includes most expert specialists with more than 35 years of experience including usage of laser equipment, elevation, and straightness of rotating machineries in various industries in parallel with unique devices which has been innovated and fabricated by our company’s experts.

We are capable of using the high-quality system to carry out the following jobs with precision, on time and reasonable prices as per follows:

- Shaft Alignment of the machineries such as Turbo Generators, Turbo Compressors, Turbo pumps, huge size Electromotors, etc.

- Straightness and Geometry adjustment including as per follows:

A: ELEVATION & LEVELING.

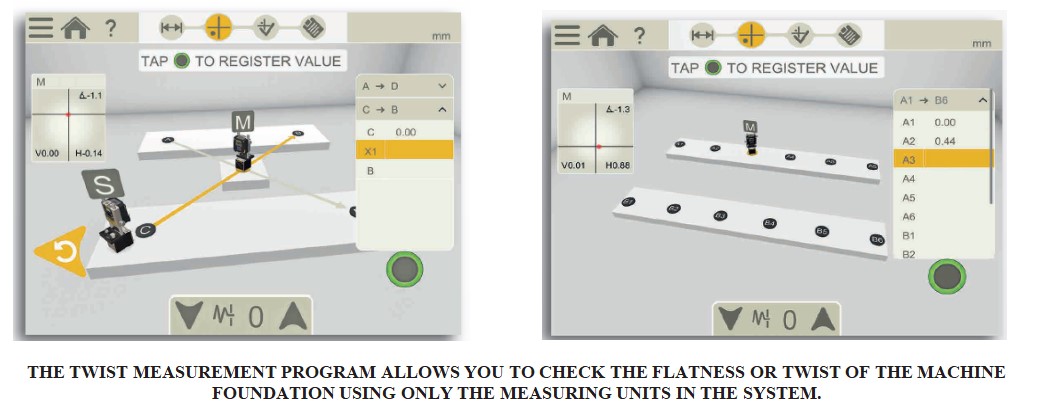

B: TWIST MEASUREMENT AND FLATNESS.

C: TWIST MEASUREMENT OF MACHINE BASE

D: MEASUREMENTS AND STRAIGHTNESS (SKIDS AND ROTATING AXIS)

- Straightness using LINE BORE Method by usage of newest Laser devices as per following:

A: Gas Turbine vertical casing alignment instead of dummy shaft.

B: Gas Turbine casing horizontal alignment.

C: Diaphragm straightness and stationery blade carriers of any machinery.

- Adjustment and straightness of Generators Bearing pedestal by stator axes.

- Erection of rotating machinery and engineering supervision services by laser devices.

VERTICAL/FLANGE MOUNTED MACHINES

For measurement and alignment of verti cally and flange mounted machines.

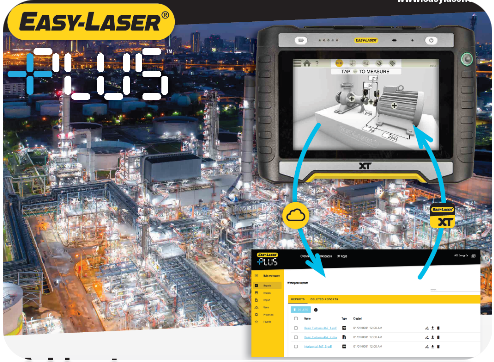

We would like to pay your kind attention concerning Laser Equipment to XT VERSION is the last version of EASY LASER which has been considered as the most advanced, sophisticated, and precise Straightness and Measurement System, uniquely applied.

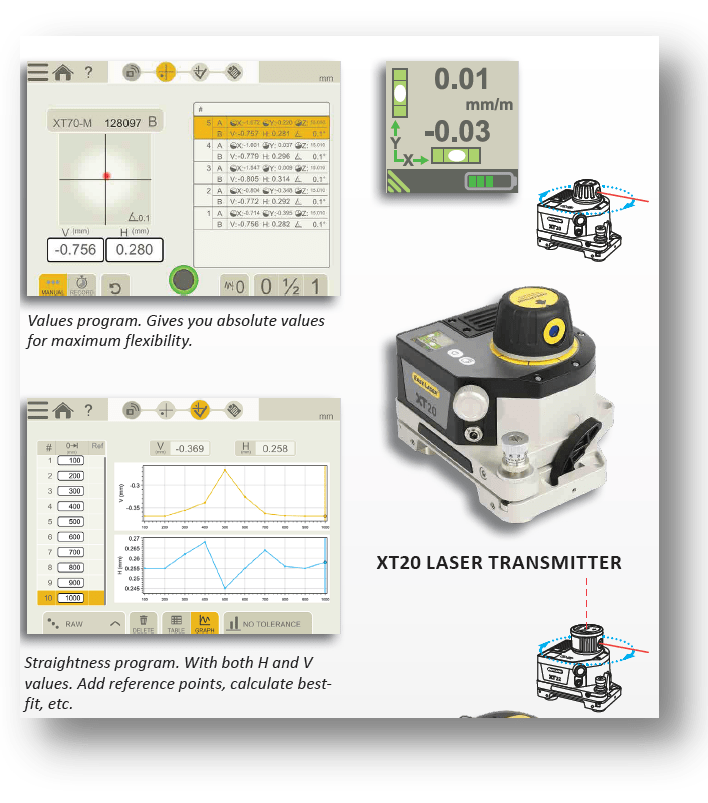

Easy-Laser is the most powerful amongst our Generation XT shaft alignment systems. Built upon our ground-breaking cross-platform technology, it is giving you the freedom to work with the display unit that suits you and the job best. Simply download our straightforward XT application for free and you have all the measurement programs you need.

EASY LASER LINE BORE Apparatus has the capability of both horizontal and vertical straightness for various rotating machinery, multi usage applications which has been coupled by flange.

Both transmitters have a 360° rotatable laser head. XT22 can in addition also point the laser beam verti cally. Their unique digital precision levels mean the accuracy will not be affected by user interpretation or possible bad work light conditions.

The transmitters connect to the XT Alignment App, making them very easy-to-use. For example, you are guided on-screen when calibrating the electronic levels. This makes the procedure easy also for users less experienced of flatness measurement. You can of course also measure with an object as reference instead of the level. The Straightness and Flatness programs then also guide you and make optimized calculations of best-fit for you. Actually, with the Values program you can perform almost any kind of geometrical measurement, although you might need to do some manual calculations.