The multi-port ball valves for gas and diesel fuel supply paths for V94.2 gas turbines.

Given the numerous power plants equipped with Siemens, Ansaldo, and Mapna V94.2 gas turbines, Class Company established one of its branches to supply auxiliary equipment for these turbines. Currently, the company works closely with most power generation management companies, and in addition to supplying all mechanical, electrical, and instrumentation equipment, firefighting systems, and other parts, it is able to provide necessary valves for industries through Hartmann Valves Germany.

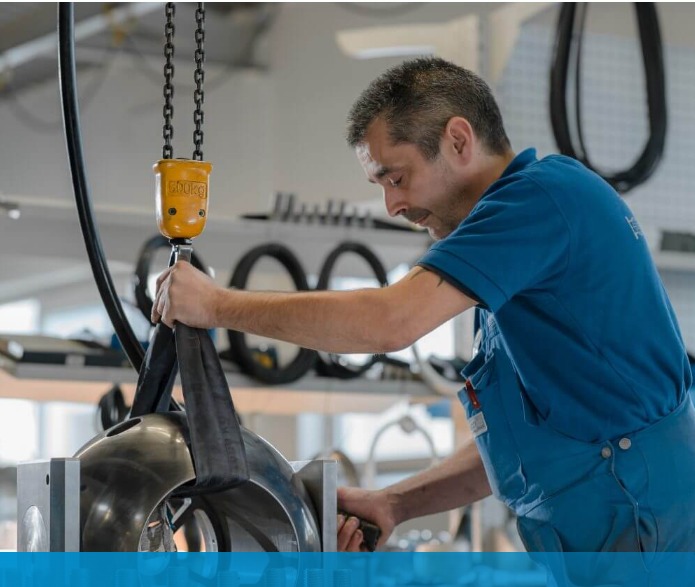

HARTMANN VALVES GMBH, Germany, with over 70 years of experience in designing and manufacturing specialized ball valves and developing METAL TO METAL SEATED BALL VALVE technology for use in the power industry, along with actuators, MOV, and accessories, takes responsibility in international markets.

Hartmann is highly interested in expanding its activities in the Iranian market. Among the special products of Hartmann, it offers actuators and multi-port ball valves for the fuel supply paths (gas and diesel) of V94.2 gas turbines manufactured by Mapna Turbine (Toga), ANSALDO, and SIEMENS. These products have received technical approval from renowned companies and have undergone performance tests, proving to be highly efficient and precise.

When this product was first introduced to the Iranian market, in cooperation with the Kerman Power Generation Management Company, two actuators from this company were tested in a power plant. The received reports indicated improved accuracy, faster action, higher thermal resistance, and the elimination of leakage in the valve, compared to the previous mechanism.

Based on the recommendations of the manufacturers’ consulting groups and experts from Mapna Turbine (Toga), Siemens, Ansaldo, and other Iranian customers and users, Hartmann products have been upgraded, and since 2022, their design has been updated. Power plants such as Shervan, Shahrood, Zowareh, Zagros Kowsar, and Rudshor are now in operation, and satisfaction letters from them can be provided.

Hartmann’s references in the oil and gas industry include Nouri Petrochemical (Borzuyeh), Tondgooyan Oil Refinery, Tabriz Oil Refinery, and Bu Ali Sina Petrochemical.

The advantages of Hartmann actuators compared to similar models can be summarized as follows:

Use of Direct Drive System instead of the old motor-gearbox and belt coupling system for power transmission:

In the old mechanism, a plastic belt was responsible for power transmission. Due to the high temperature in the turbine combustion chamber, the belt lost its original elastic properties after a short time, leading to incomplete closure of the valve and leakage. It also caused poor feedback transmission, occasionally resulting in emergency shutdowns. In Hartmann actuators, using the advanced Direct Drive technology, all the above issues are resolved.

Easy access to internal actuator components is one of the prominent features of this product, allowing for easy replacement of parts in situ during overhauls.

No need for continuous servicing and greasing: Old actuators with motor and gear systems required continuous servicing and greasing. Delays in this process resulted in grease contamination, ultimately causing gear breakage and emergency shutdowns. However, in Hartmann’s new actuators, the use of Direct Drive technology and special self-lubricating (self-sliding) gears has resolved this issue.

Hartmann actuators are designed to operate at temperatures above +140°C, are explosion-proof, and have been approved by Siemens.

Optional monitoring of the open, semi-open, and closed valve positions in the control room is another capability of this product.

Hartmann actuators and valves are fully interchangeable with older models without any change to the existing system. It is worth noting that Hartmann valves are designed and manufactured to match the dimensions, appearance, technical specifications, and connection points of older valves, ensuring minimal additional costs for the customer.

Further technical details, complete documentation, and comparisons of Hartmann actuators and valves with the old mechanism models will be provided.

It should be noted that enhancing customer satisfaction is the core strategy of Class Company. To achieve this, the company is fully committed to delivering Hartmann products quickly and on time, at competitive prices compared to similar models, providing immediate access to original spare parts, and offering long-term warranties and after-sales services.

Undoubtedly, the economic development and growth of a country, or a strategic industry such as power generation, depend on the growth of talents, utilizing all available capacities and potentials, trusting in capabilities, and wise management.

Hartmann Ball Valves “true metal to metal seated” are used in following applications

- Crude oil

- Natural Gas

- Liquid Gas

- High pressure ball valves up to Class 2500 Ansi ( 420 bar working pressure )

API 10.000 ( 690 bar working pressure )

- Wellhead or Christmas trees Valves acc. To API 6A

- ESD Emergency shut down ball valves ( max. 2 sec. to close )

- Low temperature ( approx. -140°C ) ball valves

- High temperature ( approx. +500°C )

- Lock hopper ball valves

- Oxygen ball valves

- Slurry ball valves

- High cycle ball valves

- Mining ball valves

- Ball valves in alcoholic Mediums like Ipshorb, hypshorb etc. “IFP license”

- Turret ball valves ( FPSO applications )

- Multi port ball valves ( Twin ball valves )

- Pig launcher and receiver ball valves

- Piggable tree way valves

- Ball valves in all well none material up to Titanium

- Valves in full bore and reduced bore available