Klass Industries Consulting Engineers, in collaboration with its business partners, is a leader in providing reverse engineering services, manufacturing, repair, and refurbishment of various industrial valves, designing and producing spare parts, hydrostatic testing, valve calibration, and specialized consulting and training services.

Following the cooperation agreement established, this company is able to offer a range of services to the subsidiaries of the Ministry of Energy as well as neighboring countries’ markets in the form of a consortium.

• Specialized repairs of power plant valves

• Replacement and installation of fuel supply actuator systems and operational training

• Manufacturing internal parts and refurbishing valves

• Supply of spare parts

• Hydrostatic testing and calibration of valves

• Consulting and operational training

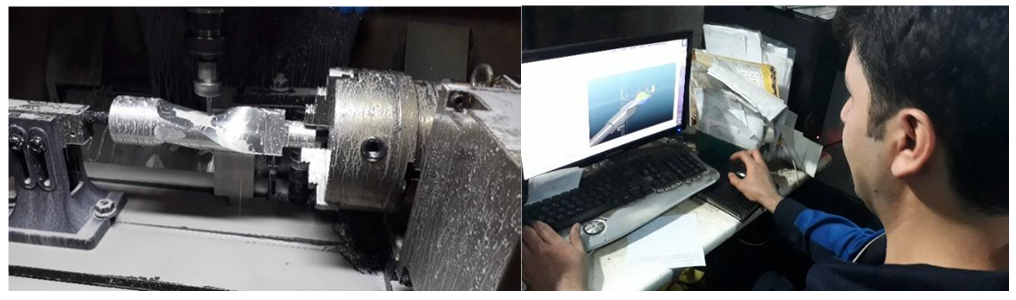

1) Valve Manufacturing: The design, reverse engineering, and manufacturing of special valves (Special Valves) in terms of materials, design, application, standards, etc., as per the clients’ requirements. The ability to manufacture all types of industrial valves, leveraging the technical knowledge and experience of the management and personnel at Klas Industrial Consultants, using the best materials and based on valve manufacturing standards, is at the core of the services provided to our esteemed clients.

2) Spare Parts Manufacturing: The manufacturing of valve components such as stems, member closures, including balls (up to 36 inches), plugs, discs, seats, back seats, glands, as well as spare parts like packing, gaskets, various O-rings, and injection grease components, is one of the services provided by the company. In the design and manufacturing of components, factors such as material, tolerance, surface finish, physical and mechanical properties, and the requirements of manufacturing or repair standards are carefully considered.

3) Specialized Repair of Industrial Valves: This includes refurbishment services for various types of industrial valves, such as ball valves, plug valves, safety valves, wellhead valves, gate valves, control valves, globe valves, check valves, butterfly valves, and pressure-reducing valves. The repairs are carried out in accordance with international standards for valve repair and manufacturing.

4) Hydrostatic Testing and Valve Calibration: To ensure the quality of valves and equipment purchased from domestic and international markets, this company provides hydrostatic testing services based on international standards. Upon request, testing can be conducted in the presence of inspectors, and a valid certificate will be issued for the valves. The company is equipped with facilities to conduct hydrostatic testing for pressure classes ranging from 150 to 2500, and sizes from ½” to 48” for various industrial valves. Additionally, calibration of control valves and adjustment of safety valves are part of the services offered by KLAS Consulting Engineers.

5) Consulting and Training: In order to enhance the knowledge of individuals involved with industrial valves and prevent damage caused by lack of technical information, KLAS Consulting Engineers includes the organization of various training courses related to industrial valves as part of its activities, providing guidance to valued customers.

Key Achievements:

1) Ball Valve Manufacturing Machine: Including machining and grinding of balls up to 36 inches.

2) Rebuilding of 24” 900# VALVE BALL and 18” 900# VALVE BALL of the METALSEATED sealing type with a CARBIDE TUNGSTEN coating.

3) Rebuilding of over 20 gate valves ranging from sizes 30″ to 48″.

4) Rebuilding of 150# 48″ Gate Valves.

5) Rebuilding of Ball Valves, Metal Seated Sealing (Tungsten Carbide) with Superalloy Inconel Material, as well as Rebuilding of Pilot Operated Safety Valves and Setting Their Set Points, and Repairing Dual Plate Check Valves up to 20 inches and up to Pressure Class 2500.

6) Repair, Testing, and Calibration of Control Valves up to 10 inches, up to Pressure Class 1500.

7) Reconstruction of 20″ 600# All Welded Ball Valves belonging to the Fourth Region of Iran Gas Transmission Operations.

8) Reverse Engineering and Manufacturing of 18″ * 16″ Class 150 Control Butterfly Valve.

9) Manufacturing of Internal Parts (Including Stem, Ball, Seat, etc.) for Orbit (KV) Valves, Manufactured by Control Seal Netherlands.

Some of the capabilities of this consortium are as follows: